Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Core Components: Plc, Motor

Status: New

Core Selling Point: Easy To Operate

Applicable Industry: Manufacturing Plant

Packaging: Pallet/Case

Productivity: 300 Sets/Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 300 Sets/Month

Port: Shanghai

Payment Type: T/T

Incoterm: FOB,CFR,CIF,EXW

The production line of high speed fin machines standard series is mainly included feeding system, fin stamping system, fin cutting system and electrical system of mold installation (only for 3G Fin Machine). Comparing to 1G and 2G fin machines, 3G Intelligent Fin Forming Machine may easily adjust the fin height by control botton which makes fin production more convinient and save much debugging time.

Controlling fin production process is as follows:

⑴Feeding system:

Material strip intelligently and automatically feeds or stops feeding according to the stamping system signal. During the feeding process, the material strip enters the pressure belt after oiling on both sides and scraping off the excess lubricating oil.

⑵Stamping system:

The material strip is stamped into needed fins through mechanical linkage and mold stamping in fin forming machine. 3G intelligent fin forming machine is the main machine of stamping fin production line, stamping fin quality by mechanical linkage and fin mold precision to achieve. In addition, high speed intelligent automatic fin production is designed with lubricating oil pump and lubricating oil distribution circuit to lubricate the bearing points of all moving parts to ensure the fin machine smoothly operated.

⑶Cutting system:

The formed fin strip is stably delivered through the synchronous spiral feeding device with stamping fins. Electrical intelligent automatic control system performs the instruction of cutting fins off through the code setting of servo motor according to the user's fin specifications data requirements. Meanwhile, the monitor shows stamping speed and cutting fin statistics.

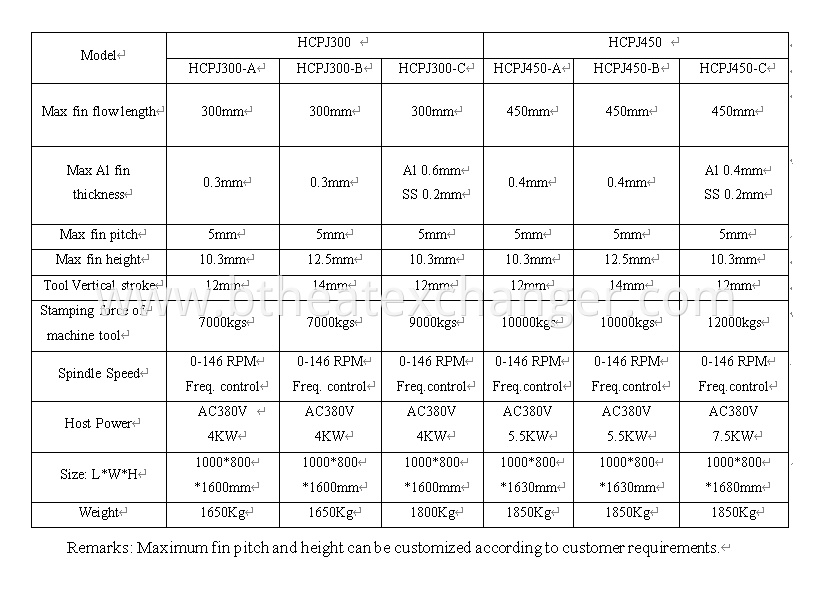

Fin Machine Main Parameters list

Product Categories : Heat Exchanger Production Machinery > Heat Exchanger Fin Machine

Home > Products > Heat Exchanger Production Machinery > Heat Exchanger Fin Machine > High Speed Fin Machines Standard Series

Send Inquiry

Ms. Joy Lee

Tel:86-510-85258875

Fax:

Mobile Phone:+8613771185563

Email:sales@btheatexchanger.com

Address:Zhaoxia rd, Mashan Town, Binhu District, , Wuxi, Jiangsu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.