Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Packaging: Pallet/Case

Productivity: 3000PCS/Month

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 5000PCS/Month

Payment Type: T/T

Incoterm: FOB,CFR,CIF

Locomotive engine heat, left uncontrolled, can damage engine parts and shorten the life of the engine and its attached components. An effective radiator system keeps the engine and components at the optimum operating temperature, regardless of whether the locomotive is operating in mountains or flatlands or hot or cold. A locomotive radiator system primarily cools air, water, and oil. The air is used in the combustion process; the water for cooling the engine and turbo (if equipped); and oil for lubricating the engine components.

The radiator system is intended to keep the engine operating at nearly the same temperature, regardless of the ambient air outside the locomotive. This allows maximum horsepower to be available at all times and extends the life of the engine and its lubricants.

Product Feature

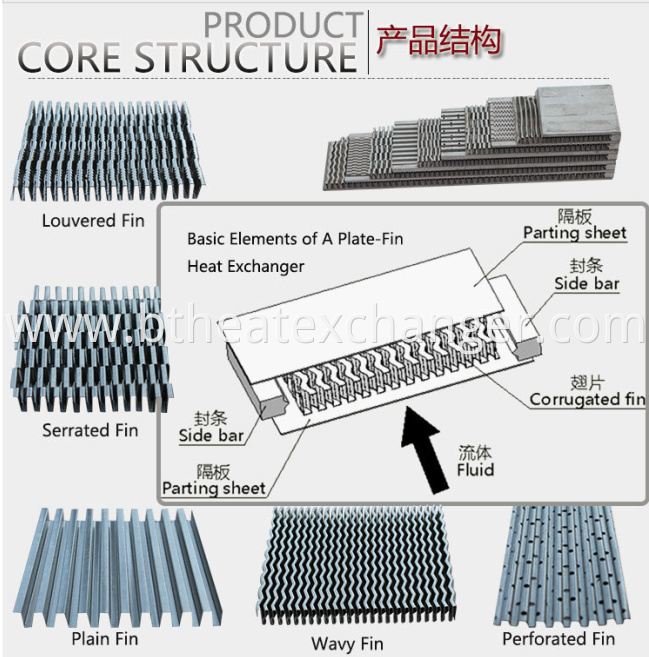

1. Railway Locomotive Cooler, Aluminum Core with compact construction and efficient heat transfer.

2. Aluminum plate and bar type Oil Cooler, Water Cooler, Air Cooler

3. Use ambient air cooling by fan, energy saving and environmental protection.

Customize coolers upon your drawing or sample or technical parameters .

Aluminum Core : High strength, high heat conductivity,high safety coefficient.

Supersonic Cleaning: High efficiency,little corrosion to metal , few pollution.

Vacuum Brazing : Strict control of vacuum degree, temperature and time.

Argon Welding : Weld Gaps straight appearance , squamous uniform.

Test : Air tightessn test , Hydraulic Pressure

Packaging

1)Export Pallets/ Plywood Case

2) According to your request

FAQ

Q1:Could you customize oil cooler/heat exchanger?

We can manufacture plate-fin heat exchanger/oil cooler /intercooler according to your drawings or samples.

Q2: I want to buy your products, how can I pay?

A :You can pay via T/T

Q3: How can you guarantee the quality?

A: One year's warranty against B/L date.

Q4: If we don`t find what we want on your website, what should we do?

A: You can email us the descriptions and pictures of the products you need, We will check whether we can make it.

Q5: Can we buy samples of each item for quality testing?

A: Yes, we understand quality test is important and we are glad to send the sample for quality testing.

Q6: What is the lead time?

A: Normal : Plate-fin heat exchanger for 2~3 weeks; Tube&fin or stacked layer coolers for 5 weeks. Exact time upon negotiation .

Product Categories : Heat Exchanger Application > Railway Locomotive Cooler

Home > Products > Heat Exchanger Application > Railway Locomotive Cooler > Aluminum Radiators For Locomotive Engine

Send Inquiry

Ms. Joy Lee

Tel:86-510-85258875

Fax:

Mobile Phone:+8613771185563

Email:sales@btheatexchanger.com

Address:Zhaoxia rd, Mashan Town, Binhu District, , Wuxi, Jiangsu

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.